We pray for prosperity of your company.

サンワ株式会社

Fully Automatic Crimping Machine MODEL:PC-40

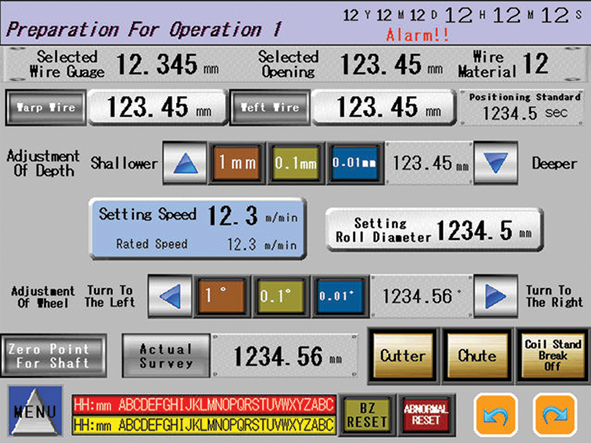

All settings can be made from a touch panel ( NC system incorporated)

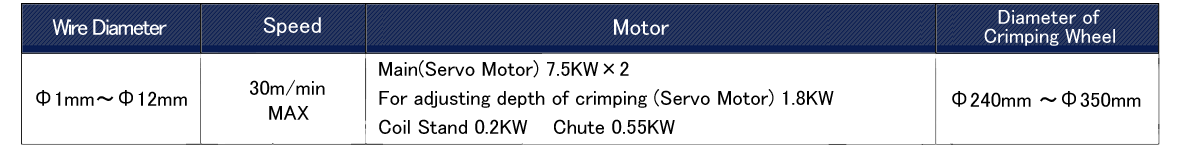

Speed Can freely be set up to a max. 45m/min. from a digital display.

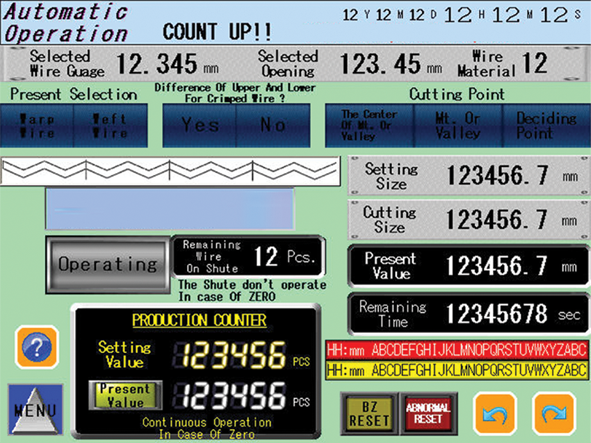

Length Setting Set on a counter. The main shaft is driven by two -- upper and lower -- strong a servomotors, thus obtain high-precision measurement.

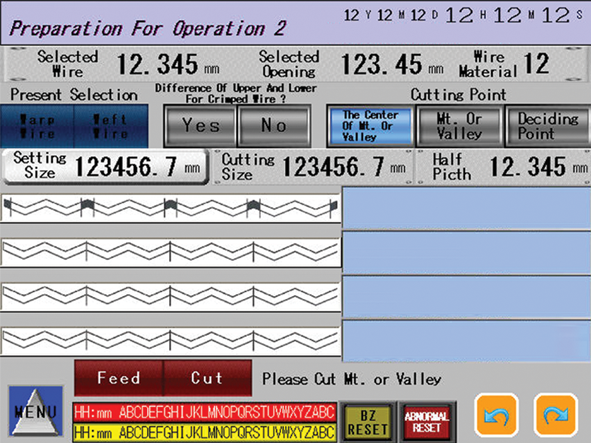

Cutting You can cut anywhere you want to cut, which was not possible with earlier machines, therefore you do not need to cut the

wire again in another process. (Material loss is reduced.) (This feature is particularly effective with flat top type.)

Crimping Depth The crimping wheel can be moved up and down by servomotor and the depth can be adjust in 1/100mm increments from

a digital display, and it can be recorded.

Accuracy of A servomotor is installed on reach shaft of the crimpoing wheel. therefore there is no extra mechanical clearance. Moreover,

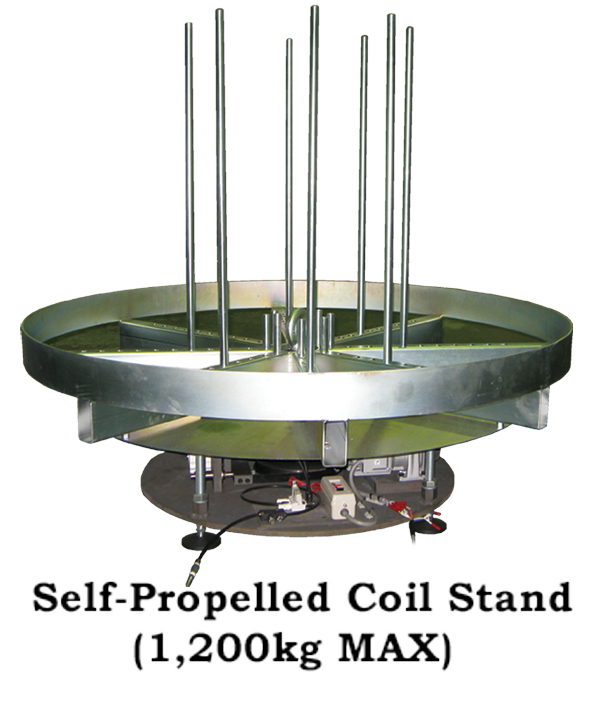

Crimping Pitch thanks to inverter control and self-properlled coil stand, the crimping speed and wire feeding speed are electrically

synchronized only by entering the coil diameter and so on, resulting in high-precision crimping.

Crimping Shape The balance can be easily adjust and recorded, therefore you can immidiately and accurately crimping using recorded data.

Balance

Coil Stand The coil stand is self-propelled, can be used with coils of max. 1,200kg and supports both right -and left-handed coils.

Machine Stopping ・ When the preset crimped wire count is reached

・ When materials run out

・ When any trouble such as tangled materials occurs. (the trouble area will be displayed.)

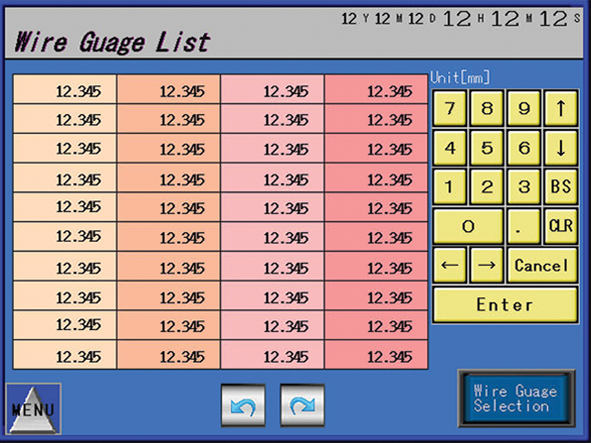

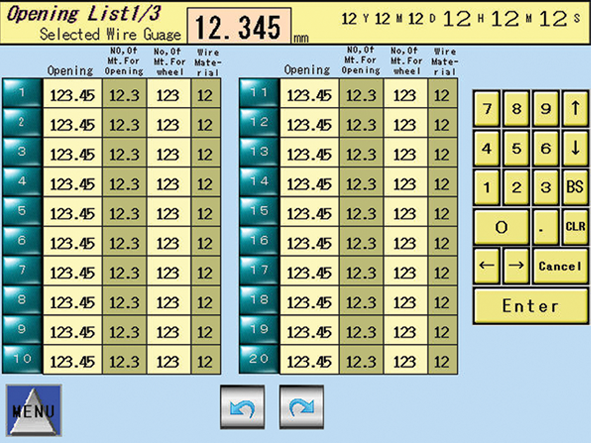

Example of Touch Panel (Screen)

Specifications

( There is a case to change the specifications without an announcement.)

◆ The Movie of PC-40 is here ◆ ⇒