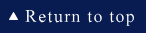

Semi Automatic Crimped Wire Mesh Weaving Machine MODEL:MW

Features (With Numerical Control)

Features (With Numerical Control)

◎ The Control Regulation is

NC System (

With Numerical Control)

◎ The behavior of each part ( can behave separately )

◎ You can make machine recall each data when you produce same mesh that you have done before without adjustment becausethe machine can memorize

working for each parts.

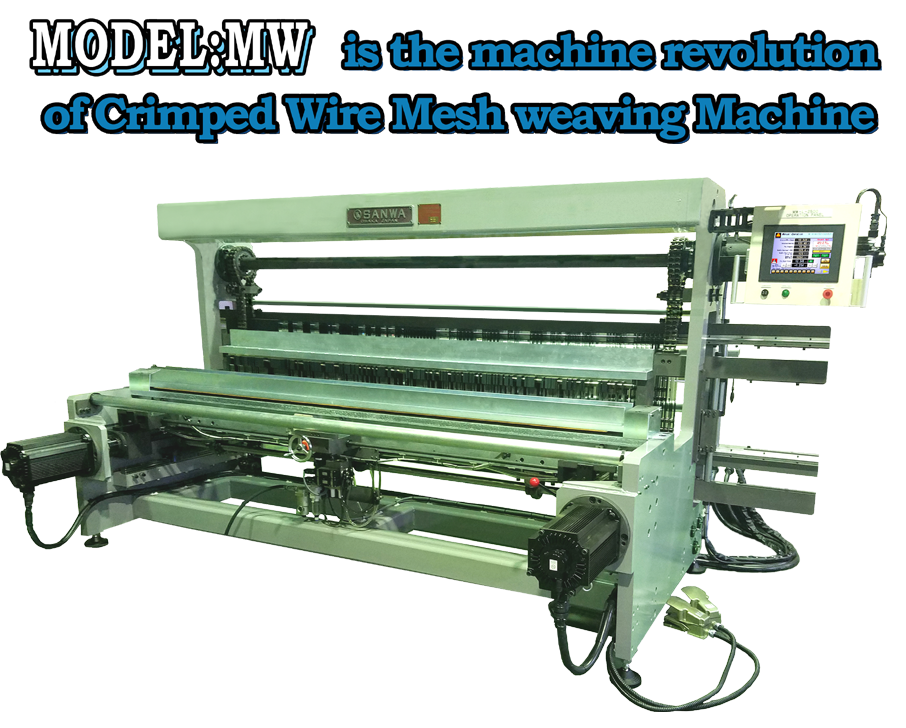

Heddle

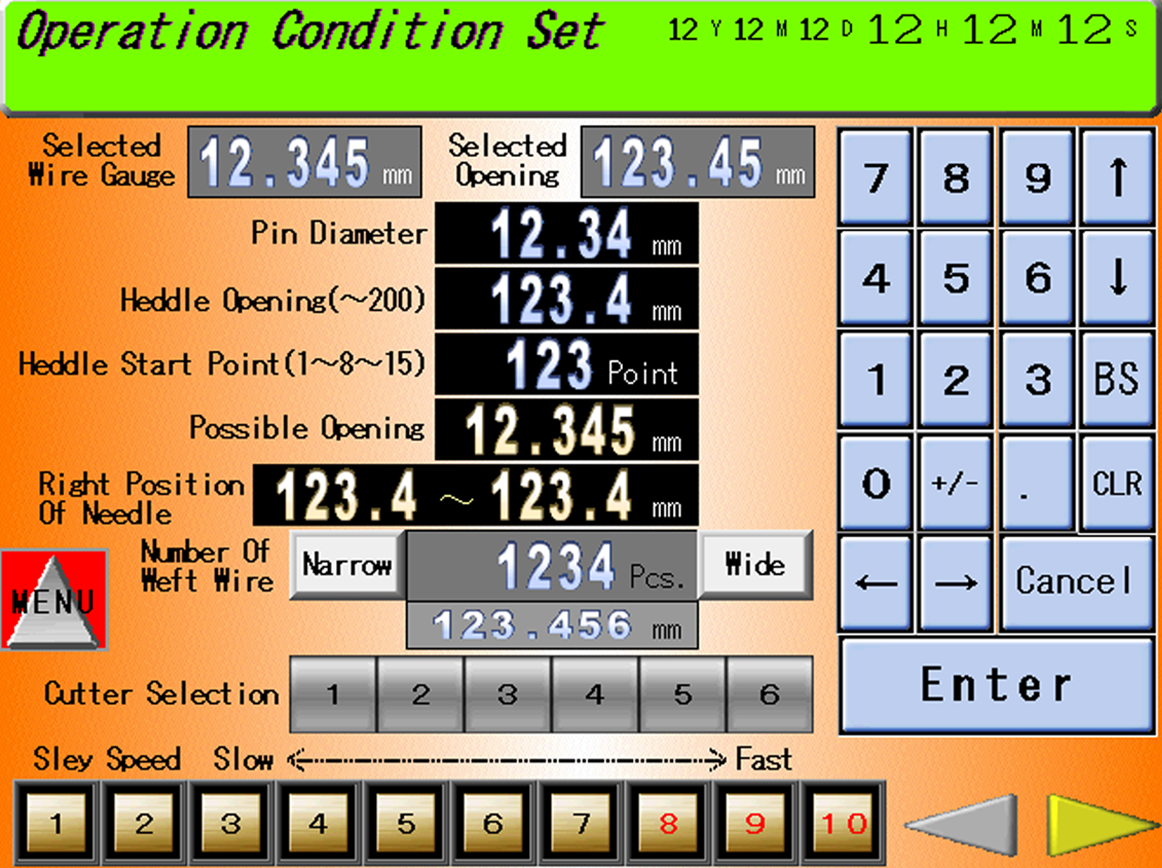

● The opening size of heddle = Can set easily 0 mm〜200 mm by touch screen panel.

● The changing timing of heddle frame = Can change easily by touch screen

panel.

Sley (Reed)

○ The pitch operation = It is very convenience to use this before continuous operation and just before the end of warp wire . ( Decrease of waste for warp wire )

● Can change the stroke of sley and weave with keep to stop its behavior

of crimped wire mesh. ( Can change the stroke of sley by touch screen panel

)

● Can change the speed of just sley depend on the kind of crimped wire mesh.

Needle

● The needle can insert into place of crimped wire mesh with getting out

the timing electrically absolutely .

● The injury of needle decrease compare with previous model constitutionally.

At the time of operating abnormality

● When the operating abnormality happened , it will be shown by touch screen

panel where is the problem .

Operation Condition Set by the Touch Panel Screen

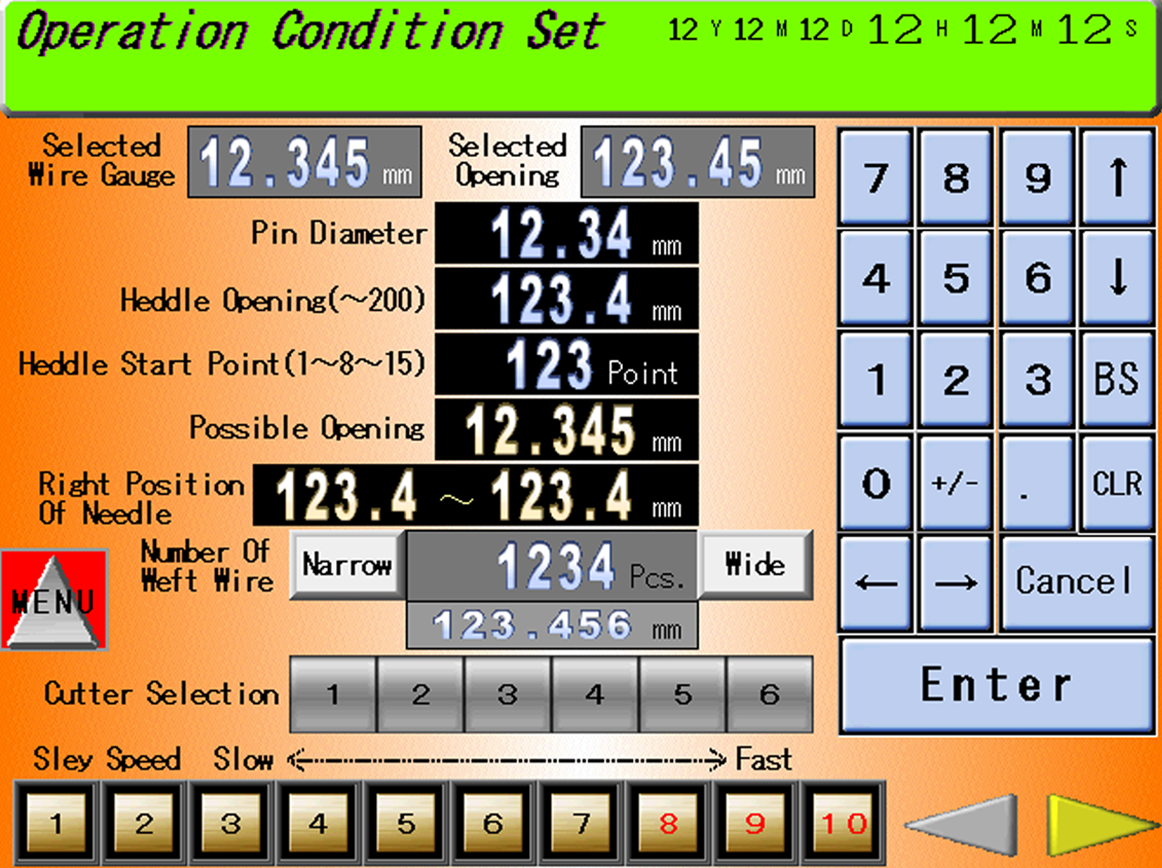

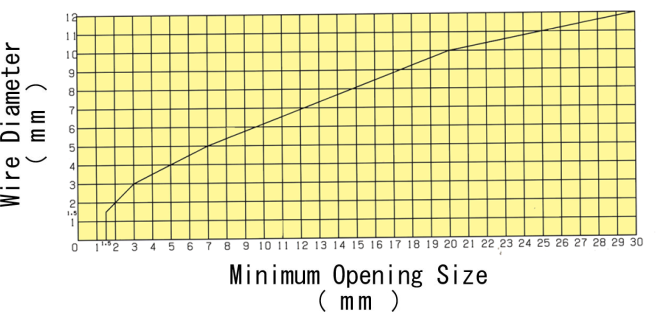

The minimum opening size of possible to weave with wire diameter

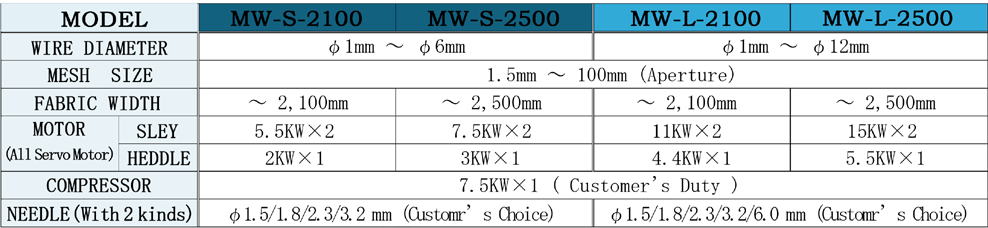

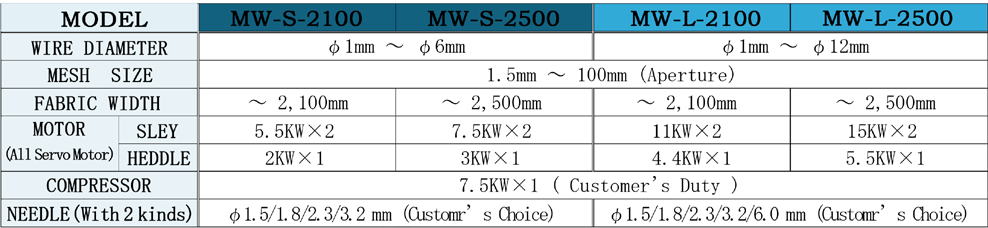

SPECIFICATIONS

◆ The Movie of MW-L-2500 is here ◆ ⇒

◆ The Movie of MW-L-2500 is here ◆ ⇒

OR